Welcome to Our Company -

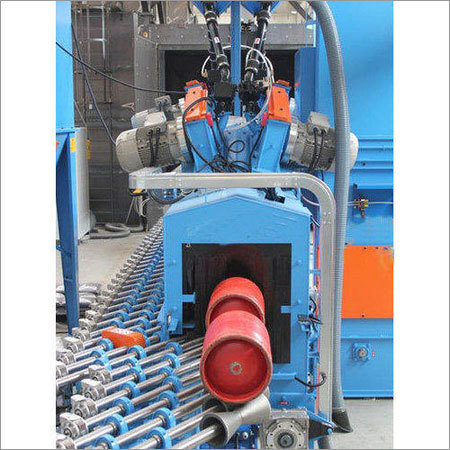

LPG Cylinder Shot Blasting Machine

300000.00 INR/Piece

Product Details:

- Motor Type Electric Motor

- Capacity 50-70 LPG Cylinders per hour

- Dimension (L*W*H) 6600 x 4200 x 3800 mm

- Weight Approx. 7800 kg

- Application Cleaning & Surface Preparation of LPG Cylinders

- Power 17-22 kW

- Voltage 415 V, 3 Phase, 50 Hz

- Click to view more

X

LPG Cylinder Shot Blasting Machine Price And Quantity

- 1 Piece

- 300000.00 INR/Piece

LPG Cylinder Shot Blasting Machine Product Specifications

- 415 V, 3 Phase, 50 Hz

- 17-22 kW

- Electric Motor

- Approx. 7800 kg

- Cleaning & Surface Preparation of LPG Cylinders

- 50-70 LPG Cylinders per hour

- Automatic Flow-Through Conveyor

- 6600 x 4200 x 3800 mm

LPG Cylinder Shot Blasting Machine Trade Information

- 10-15 Piece Per Month

- 1 Months

- Standard Packaging

- Western Europe, Australia, North America, South America, Eastern Europe, Middle East, Central America, Africa, Asia

- All India

Product Description

Known for its Long working life,Low maintenance cost and High efficiency, this LPG Cylinder Shot Blasting Machine is widely demanded in the market. The cylinders rotates at the time of moving forward & shot blasted inside the blast chamber. It is widely used for granite, sand stones, cement concrete interlocking paving block, marble panels, etc. In order to manufacture this machine, our experts make use of the premium grade raw material and advance technology a keeping in mind the international quality norms. We offer this LPG Cylinder Shot Blasting Machine at the most affordable rates.

Superior Cylinder Cleaning Efficiency

This shot blasting machine is tailored for LPG cylinder manufacturers and refurbishers, ensuring thorough rust, scale, and old paint removal. Its high-performance blasting wheels, made from resilient manganese steel, deliver a uniform, contamination-free finish that extends cylinder lifespan and enhances safety compliance.

Automated & Customizable Operation

Designed with advanced automation, the system offers flexible blasting wheel quantity and conveyor speed. The PLC-controlled interface allows for precise adjustments, accommodating various production needs and cylinder sizes while reducing operator intervention and maintenance.

Integrated Safety & Environmental Control

Equipped with an efficient dust filtering system and engineered for low noise (<85 dB), the machine meets strict workplace safety and environmental standards. Its sturdy construction ensures durability under heavy-duty use and continuous industrial operation.

FAQs of LPG Cylinder Shot Blasting Machine:

Q: How does the LPG Cylinder Shot Blasting Machine operate?

A: The machine uses high manganese steel blasting wheels to propel abrasive media onto LPG cylinders conveyed through its automatic roller or chain system. Controlled by a PLC panel, it cleans and prepares surfaces to SA 2.5 standard with minimal manual intervention.Q: What types of cylinders and sizes are compatible with this shot blasting machine?

A: This machine supports LPG cylinders with diameters ranging from 220 to 420 mm, making it suitable for a wide variety of domestic and industrial LPG containers.Q: When should the shot blasting process be used for LPG cylinders?

A: Shot blasting is recommended prior to painting, recoating, or inspection of LPG cylinders. It effectively removes rust, scale, and old coatings, ensuring the surface is clean and adequately prepared for subsequent processing.Q: Where can this machine be installed and who benefits most from its use?

A: Ideal for installation in cylinder manufacturing plants, refurbishment centers, and large-scale metal fabrication facilities, it is a valuable asset for exporters, manufacturers, and suppliers seeking consistent quality and productivity.Q: What is the process flow for cleaning LPG cylinders using this equipment?

A: Cylinders are loaded onto the automatic conveyor system, passed through the blasting chamber where steel shots or grit remove contaminants, then exit with a uniform SA 2.5 surface finish, ready for further treatment or painting.Q: How does the integrated dust collection system work?

A: The system features an efficient cartridge or bag filter dust collector that captures blasting residues and airborne particulates, maintaining clean air quality and ensuring compliance with industrial safety standards.Q: What are the main benefits of using this fully automatic shot blasting machine?

A: It offers high throughput (5070 cylinders/hour), uniform surface finish, reduced labor, enhanced safety, and improved coating adhesion, which together result in operational efficiency and long-term cost savings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese