Welcome to Our Company -

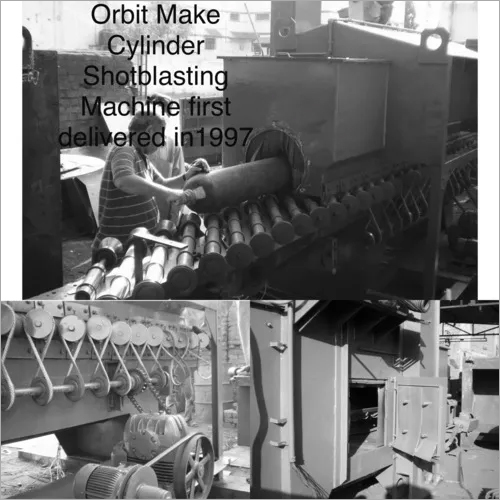

CNG Cylinder Shot Blasting Machine

3855207 INR/Piece

Product Details:

- Motor Type Electric Motor Driven

- Capacity 2-4 Cylinders per batch

- Dimension (L*W*H) 3200 x 1500 x 2100 mm

- Weight 1850 kg

- Application CNG Cylinder External Surface Cleaning

- Power 12 kW

- Voltage 415 V

- Click to view more

X

CNG Cylinder Shot Blasting Machine Price And Quantity

- 1 Piece

- 3855207 INR/Piece

CNG Cylinder Shot Blasting Machine Product Specifications

- CNG Cylinder External Surface Cleaning

- 2-4 Cylinders per batch

- Electric Motor Driven

- 12 kW

- 1850 kg

- 415 V

- Robust Enclosed Cabinet Design

- 3200 x 1500 x 2100 mm

CNG Cylinder Shot Blasting Machine Trade Information

- 10-15 Piece Per Month

- 1 Months

- Standard Packaging

- Middle East, Western Europe, Africa, South America, Asia

- All India

Product Description

Known as an admirable manufacturer of industrial machines, we are involved in providing of a premium quality CNG Cylinder Shot Blasting Machine that is widely used for surface treatment & metal finishing applications in various industries. By making use of best in class quality component, the provided machines are made with the help of latest technology under the proper supervision of our experts. In addition to this, our offered machines are available in different specifications to meet the different demands of our customers. Our valuable customers can avail this CNG Cylinder Shot Blasting Machine from us at the most affordable rates.

High-Quality Surface Cleaning

This machine achieves an exceptional surface finish (Sa 2.5 standard), removing contaminants and preparing CNG cylinders for further processing such as painting or coating. Its continuous roller conveyor mechanism ensures consistency and reliability across each batch.

Advanced Process Control and Safety

The PLC-controlled interface provides straightforward operation and process adjustment. Safety is paramount, with interlocked doors and emergency stop switches protecting operators during use. Noise emissions are kept below 85 dB(A), supporting workplace safety standards.

Efficient Production Automation

With automatic loading and unloading, variable speed conveyor drive, and the ability to clean 24 cylinders per batch, this machine enhances productivity. Its integrated dust collector and robust design support continuous operation for manufacturers and suppliers.

FAQs of CNG Cylinder Shot Blasting Machine:

Q: How does the continuous roller conveyor shot blasting process work for CNG cylinders?

A: The continuous roller conveyor shot blasting system feeds CNG cylinders automatically onto rollers that transport them through the blast chamber. Steel shots are propelled by 24 blast wheels, thoroughly cleaning the external surface as the cylinders move through at adjustable speeds.Q: What types of CNG cylinders can be processed with this machine?

A: Cylinders with diameters ranging from 220 mm to 406 mm can be efficiently cleaned. The system is designed to handle 24 cylinders per batch, making it suitable for a range of sizes commonly used in CNG applications.Q: When should I use this machine in CNG cylinder production?

A: It is ideal for use during the surface preparation stage, prior to applying coatings or conducting inspections, in order to achieve a clean surface with Sa 2.5 finish as specified by ISO 8501-1. This ensures better adhesion for subsequent treatments.Q: Where is the dust generated by shot blasting contained or filtered?

A: An integrated cartridge filter dust collector system captures and filters dust produced during the blasting process, ensuring clean operation and compliance with environmental and workplace safety standards.Q: What are the main benefits of using a PLC-controlled operator interface?

A: The PLC-controlled operator interface simplifies machine operation, enables precise adjustment of cleaning parameters such as speed and blast intensity, and helps ensure consistent, repeatable results while improving operator convenience and safety.Q: How does the machine ensure operator safety during operation?

A: Safety measures include interlocked access doors that prevent the machine from running when open and emergency stop switches that immediately halt operation if necessary. These features minimize the risk of accidents and ensure compliance with safety regulations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese