Welcome to Our Company -

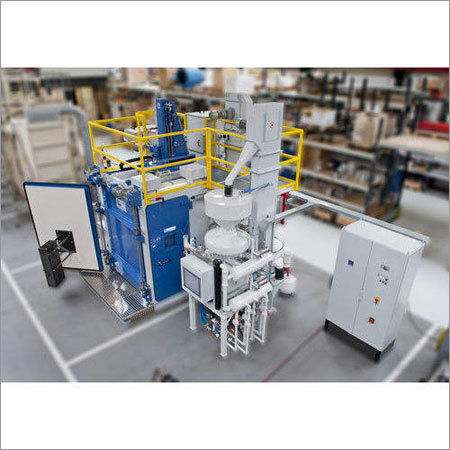

Robotic Shot Peening Machine

300000.00 INR/Piece

Product Details:

- Motor Type Servo Motor Driven

- Capacity Customizable as per Requirement

- Dimension (L*W*H) 5000 x 3500 x 3000 mm

- Weight Approx. 3200 kg

- Application Surface Finishing, Stress Relieving, Fatigue Life Enhancement

- Power 15 kW

- Voltage 380 V, 3 Phase, 50/60 Hz

- Click to view more

X

Robotic Shot Peening Machine Price And Quantity

- 300000.00 INR/Piece

- 1 Piece

- Controlled Almen Intensity

- Steel Shot, Glass Beads, Ceramic Beads

- 6 Axis Articulated Robot

- Full 3D Component Access

- Fully Automatic

- On-line Media Separation and Recycling Unit

- High Precision Programmable Nozzle

- Interlocked Door, Emergency Stop, Safety Light Curtains

- PLC Based with HMI Interface

- Adjustable, Up to 8 bar

- Programmable as per Component Geometry

- Integrated Cartridge Dust Collector

Robotic Shot Peening Machine Product Specifications

- Servo Motor Driven

- Surface Finishing, Stress Relieving, Fatigue Life Enhancement

- Robust Industrial Robotic Arm

- Customizable as per Requirement

- Approx. 3200 kg

- 15 kW

- 5000 x 3500 x 3000 mm

- 380 V, 3 Phase, 50/60 Hz

- Controlled Almen Intensity

- Steel Shot, Glass Beads, Ceramic Beads

- 6 Axis Articulated Robot

- Full 3D Component Access

- Fully Automatic

- On-line Media Separation and Recycling Unit

- High Precision Programmable Nozzle

- Interlocked Door, Emergency Stop, Safety Light Curtains

- PLC Based with HMI Interface

- Adjustable, Up to 8 bar

- Programmable as per Component Geometry

- Integrated Cartridge Dust Collector

Robotic Shot Peening Machine Trade Information

- 10-15 Piece Per Month

- 1 Months

- Standard Packaging

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- All India

Product Description

Our company is well known manufacturer of Robotic Shot Peening Machine. This machine is used for increasing the strength of different parts that are not working in a proper manner. This machine is different from a standard shot peening machine as it integrates a PLC with HMI system, programmable robot, uninterrupted media flow, parallel dual pressure pot peening system and environmentally safe. Advance techniques are used by the team of our adroit professionals for the manufacturing of widely appreciated Robotic Shot Peening Machine. It is known for its easy installation, trouble free functionality and compact design. Various custom made designs can also be created to fulfill the set requirements of customers. In addition, these are offered at very nominal prices.

Applications:

- Used in the automated peening process for quick shot peening

- Also used in various industries

- Robotic Shot Peening Machine is great to use

- Great Applications for gas turbines and aeronautics

- Can also be used for precise and high-quality performance and quality reports

Advanced Programmable Nozzle Technology

This machine utilizes a high precision programmable nozzle, enabling accurate shot placement and controlled Almen intensity. The programmable feature ensures uniform peening across intricate geometries, enhancing process efficiency and repeatability for various component types.

Comprehensive 3D Coverage and Automation

Equipped with a 6-axis articulated robotic arm, the system offers full access to complex 3D components. The PLC-based control system with HMI enables users to automate and customize cycle times based on component designs, ensuring optimal treatment and consistent results.

Integrated Safety and Dust Collection Systems

Safety is paramount, with interlocked doors, emergency stop buttons, and safety light curtains. The integrated cartridge dust collector maintains a clean environment, while the on-line media separation and recycling unit ensures media purity for consistent surface finishing quality.

FAQs of Robotic Shot Peening Machine:

Q: How does the programmable nozzle improve shot peening accuracy and coverage?

A: The high precision programmable nozzle allows for targeted shot delivery across complex component surfaces, ensuring uniform peening. Its programmability enables precise adjustments for different geometries, maximizing coverage and controlling Almen intensity for enhanced fatigue life.Q: What types of shot media can be used with this machine?

A: This unit is compatible with steel shot, glass beads, and ceramic beads, providing flexibility for various applications in surface finishing, stress relieving, and fatigue life improvement. The integrated cleaning and recycling system helps maintain media effectiveness throughout the process.Q: When is the optimal time to use robotic shot peening in a manufacturing workflow?

A: Robotic shot peening is typically employed after preliminary machining or prior to final assembly to relieve stress, improve fatigue life, and enhance surface finish. It is especially recommended for components subject to cyclic loads and demanding operational environments.Q: Where can this machine be installed, and what are its space requirements?

A: The machine should be installed in an industrial facility with access to 380V, 3-phase power supply. Its dimensions are 5000 x 3500 x 3000 mm, requiring sufficient floor space, as well as provisions for dust extraction and safe operation in compliance with factory safety standards.Q: What is the process for adjusting peening intensity and cycle time?

A: Operators can adjust peening intensity via the HMI interface and PLC controls, setting blast pressure up to 8 bar and programming cycle times to match component geometry. These settings allow for tailored treatment, from gentle surface conditioning to deep stress relief as needed.Q: How does the integrated dust collector and media recycling unit enhance operational safety and efficiency?

A: The cartridge dust collector captures airborne particles, maintaining a cleaner work environment and protecting operators. The on-line media separation and recycling unit removes debris from shot media, ensuring only clean media contacts components for optimal finishing and consistent quality.Q: What are the key benefits of using this fully automatic robotic shot peening machine over manual systems?

A: This machine provides full automation, reduced operational errors, consistent process control, improved safety with interlocks and emergency stops, customizable capacity, and reliable fatigue life enhancement. Its robust robotic arm ensures precise 3D coverage for high-quality surface finishing across varied industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free