Welcome to Our Company -

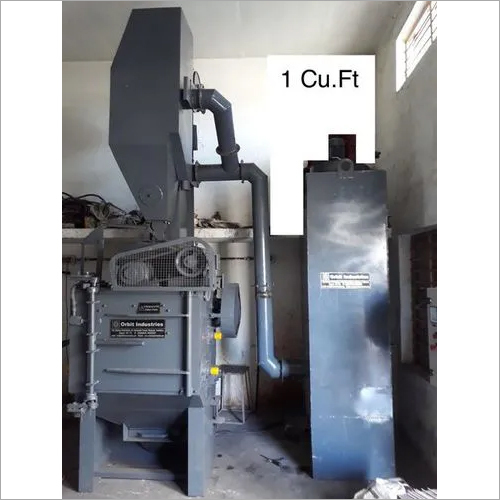

Tumblast Shot Blasting Machine

300000.00 INR/Piece

Product Details:

- Motor Type Electric, Three Phase

- Capacity 200 kg per batch

- Dimension (L*W*H) 1450 x 1200 x 2150 mm

- Weight 1200 kg

- Application Cleaning, surface preparation, descaling of small to medium metal components

- Power 5 HP

- Voltage 415 V

- Click to view more

X

Tumblast Shot Blasting Machine Price And Quantity

- 1 Piece

- 300000.00 INR/Piece

- Manually or pneumatically operated

- Spare blades, control cage, abrasive replenishment hopper

- Below 85 dB (A) with proper enclosure

- Cartridge/Bag-house (attached or separate)

- 2500 to 3000 RPM

- 1 or 2 (custom configuration available)

- PLC based with safety interlocks

- 4 to 8 RPM

- High-grade manganese steel lining

- Up to 1000 Kg

- 600 mm to 1200 mm diameter (model specific)

- SA 2.5 (as per ISO 8501-1)

Tumblast Shot Blasting Machine Product Specifications

- 5 HP

- 1200 kg

- Robust, fully enclosed, continuous process type

- 200 kg per batch

- 415 V

- 1450 x 1200 x 2150 mm

- Cleaning, surface preparation, descaling of small to medium metal components

- Electric, Three Phase

- Manually or pneumatically operated

- Spare blades, control cage, abrasive replenishment hopper

- Below 85 dB (A) with proper enclosure

- Cartridge/Bag-house (attached or separate)

- 2500 to 3000 RPM

- 1 or 2 (custom configuration available)

- PLC based with safety interlocks

- 4 to 8 RPM

- High-grade manganese steel lining

- Up to 1000 Kg

- 600 mm to 1200 mm diameter (model specific)

- SA 2.5 (as per ISO 8501-1)

Tumblast Shot Blasting Machine Trade Information

- Cheque

- 10-15 Piece Per Month

- 1 Months

- Standard Packaging

- All India

Product Description

With great conceit, we set up ourselves as the famous manufacturer of superior quality Tumblast Shot Blasting Machine that is mainly used in mining for demolition. The offered machine is manufactured by using durable components & advance technology by our trained professionals. To make ensure its flawlessness and long life, our provided machine is quality tested on different parameters by our quality checkers. Our advance Tumblast Shot Blasting Machine can be installed easily and can withstand various working conditions.

Features:

- Complete Mn. Steel Structure

- There is a wide range of blast wheels available.

- Soundproofing chamber

- Very effective to use

- Dust Collectors with High Efficiency

- System for intelligent equipment handling.

- Great to operate

- Tumblast Shot Blasting Machine has no need for a pit.

- Blast Wheels with High Performance

Versatile Performance and Customization

Our Tumblast Shot Blasting Machine provides highly customizable configurations, accommodating a variety of barrel sizes and blast wheel quantities. The design offers both manual and pneumatic door operation, allowing smooth integration into your workflow. It is ideal for a broad spectrum of metal component cleaning and surface treatment tasks, ensuring flexibility for different production demands.

Robust Construction for Longevity

This machine boasts a fully enclosed, robust design built with top-grade manganese steel lining. Its continuous process type construction enhances durability and minimizes maintenance needs. The integrated PLC-based control panel with safety interlocks promotes safe and reliable operation for users.

Efficient and Environmentally Conscious Operation

Featuring energy-efficient electric motors, cartridge or bag-house dust collectors, and noise suppression below industry thresholds, the machine ensures clean, safe, and environmentally considerate operation. Accessories like spare blades and an abrasive replenishment hopper come standard, ensuring uninterrupted and efficient productivity.

FAQs of Tumblast Shot Blasting Machine:

Q: How does the tumblast shot blasting machine process work?

A: The tumblast shot blasting machine works by loading metal components into a rotating barrel. As the barrel rotates between 4 and 8 RPM, one or two blast wheels propel abrasive media at high velocity (25003000 RPM), effectively cleaning, descaling, or preparing component surfaces. The process repeats until the desired surface finish, typically SA 2.5, is achieved.Q: What types of components can be processed with this machine?

A: This model is designed for small to medium-sized metal components. It is commonly used for cleaning, preparing, and descaling parts in automotive, foundry, and manufacturing industries, handling batches up to 1000 kg per cycle.Q: When should I choose a single blast wheel versus a double blast wheel configuration?

A: A single blast wheel is suitable for standard cleaning and lower throughput requirements. If you require higher productivity or more uniform surface coverage per cycle, opting for a double blast wheel configuration is recommended.Q: Where can the machine be installed, and what are the power requirements?

A: The unit is suitable for factory or workshop environments with robust floors, considering its 1200 kg weight and dimensions (1450 x 1200 x 2150 mm). It requires a three-phase electric supply at 415 V and 5 HP power.Q: What benefits does the manganese steel lining offer?

A: High-grade manganese steel lining provides exceptional resistance to abrasive wear, extending the machines service life and reducing downtime or maintenance frequency.Q: How is dust and noise managed during machine operation?

A: Dust is controlled using cartridge or bag-house dust collectors, which can be either attached or separated, depending on installation needs. The fully enclosed design and proper acoustic containment keep operating noise levels below 85 dB (A), creating a safer and more comfortable work environment.Q: What standard accessories are provided with the machine?

A: Each unit comes with essential accessories such as spare blades, a control cage, and an abrasive replenishment hopper to support efficient operation and easy maintenance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese