Welcome to Our Company -

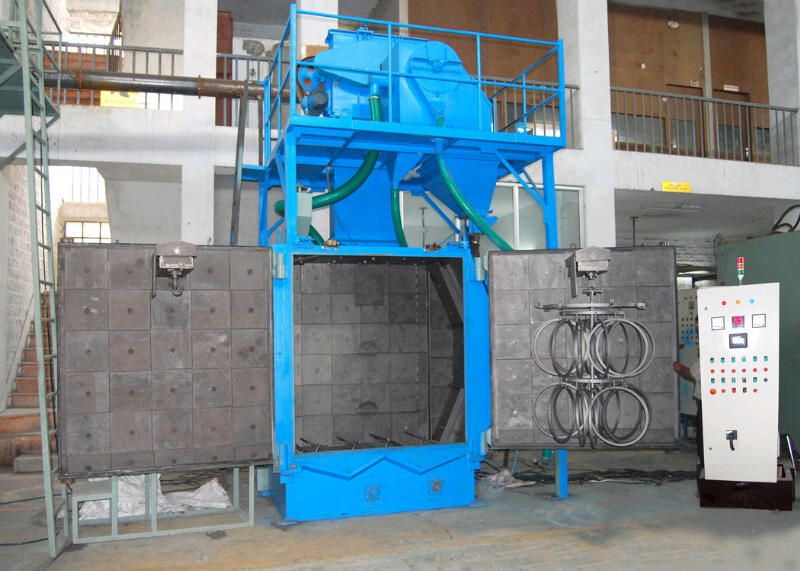

Door mounted hook Spinner Hanger Shot Blasting Machine

900000.00 INR/Piece

Product Details:

- Motor Type Three Phase Induction Motor

- Capacity 500 kg to 5000 kg (model dependent)

- Dimension (L*W*H) Customized as per model; approx. 3000mm x 2000mm x 4000mm

- Weight Approx. 3500 kg 9500 kg

- Application Surface cleaning, descaling, and preparation of castings, forgings, and welded components

- Power 10 kW to 40 kW (total installed, depending on model)

- Voltage 380V/415V, 50Hz/60Hz

- Click to view more

X

Door mounted hook Spinner Hanger Shot Blasting Machine Price And Quantity

- 900000.00 INR/Piece

- 1 Unit

Door mounted hook Spinner Hanger Shot Blasting Machine Product Specifications

- Three Phase Induction Motor

- 380V/415V, 50Hz/60Hz

- Approx. 3500 kg 9500 kg

- 500 kg to 5000 kg (model dependent)

- 10 kW to 40 kW (total installed, depending on model)

- Surface cleaning, descaling, and preparation of castings, forgings, and welded components

- Door mounted hook spinner hanger with heavy duty chamber

- Customized as per model; approx. 3000mm x 2000mm x 4000mm

Door mounted hook Spinner Hanger Shot Blasting Machine Trade Information

- 10-15 Unit Per Month

- 1 Minutes

- Standard Packaging

- All India

Product Description

With the help of our well expert team of our organization, we are involved in manufacturing an advance and easy to use Door mounted hook Spinner Hanger Shot Blasting Machine. Provided quality assured machine is made by using premium grade raw material like metal and ultra modern technology in accordance with set market norms. Our provided Door mounted hook Spinner Hanger Shot Blasting Machine is used for different applications such as cleaning of casting & various others. We use premium quality raw material for manufacturing our product & available at very reasonable rates.

Efficient Surface Preparation Solution

Designed for heavy-duty use, this shot blasting machine ensures thorough cleaning, descaling, and surface preparation of diverse metal parts. Its automatic rotary hanger facilitates even blasting, while the powerful blast wheels and wear-resistant manganese steel lining guarantee durability and productivity across applications.

User-Friendly Operation & Control

The PLC-based, HMI-equipped control panel provides intuitive operation, facilitating efficient process management and monitoring. Whether used with manual or automatic hanger rotation, operators benefit from streamlined workflows and consistently reliable results.

Flexible Design for Varied Needs

With customizable dimensions and a broad capacity range (5005000 kg), this machine adapts to specific project requirements. Multiple chamber sizes and door configurations support both small and large production volumes, making it an ideal asset for manufacturers across sectors.

FAQs of Door mounted hook Spinner Hanger Shot Blasting Machine:

Q: How does the Door Mounted Hook Spinner Hanger Shot Blasting Machine operate?

A: The machine utilizes a motorized door and a rotating hanger system to suspend workpieces. During operation, blast wheels propel steel shot or grit at high velocity onto the components, automatically removing scale, rust, and surface contaminants. The rotation ensures even cleaning across all surfaces.Q: What types of materials can be cleaned using this shot blasting machine?

A: It is suitable for surface cleaning, descaling, and preparation of castings, forgings, and welded components. Its robust design accommodates a variety of ferrous and non-ferrous metal parts used in various industrial applications.Q: When should I use a shot blasting machine with automatic hanger rotation?

A: Automatic hanger rotation is ideal for processing batches of parts needing consistent exposure to the blast stream. This feature is especially beneficial for complex or irregularly shaped workpieces requiring uniform surface treatment.Q: Where is this shot blasting machine commonly installed?

A: Such machines are typically installed in foundries, fabrication shops, and manufacturing plants engaged in surface treatment and finishing tasks for components produced in moderate to high volumes.Q: What is the process for maintaining the dust collector system?

A: The dust collector, featuring either cartridge or bag filters with pulse jet cleaning, should be checked regularly for filter integrity and cleaned or replaced as needed. Pulse jet cleaning helps maintain airflow and filter efficiency, ensuring proper extraction of dust and debris.Q: How does the PLC-based HMI benefit machine operation?

A: The PLC-based HMI (Human Machine Interface) simplifies control and monitoring, enabling operators to adjust process parameters, track machine status, and manage safety interlocks, leading to improved productivity and operator confidence.Q: What are the main benefits of using a manganese steel-lined chamber?

A: A manganese steel lining provides exceptional resistance to abrasion and wear, significantly prolonging the operational life of the blasting chamber and reducing maintenance intervals, which contributes to lower total cost of ownership.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese