Welcome to Our Company -

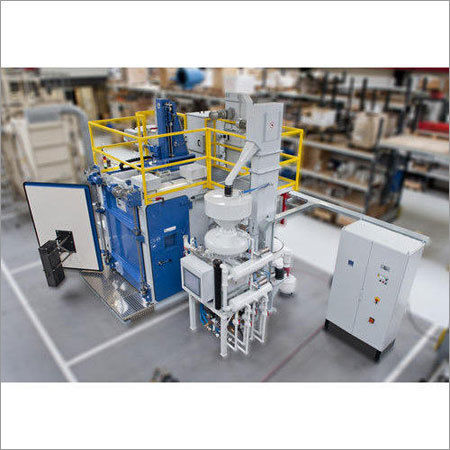

Automatic Air type Shot Peening Machine

300000.00 INR/Piece

Product Details:

- Motor Type Three Phase Electric Motor

- Capacity Variable, typically 50-300 kg/hr depending on part size and shot material

- Dimension (L*W*H) 3200 mm x 2200 mm x 3500 mm

- Weight Approx. 3800 kg

- Application Surface finishing, stress relieving, deburring, shot peening for aerospace, automotive, and metal fabrication industries

- Power 7.5 kW to 22 kW (based on model)

- Voltage 380V / 415V, 50Hz (Customizable as per requirement)

- Click to view more

X

Automatic Air type Shot Peening Machine Price And Quantity

- 1 Piece

- 300000.00 INR/Piece

- Automatic air-wash and vibratory screening

- Interlocking doors, emergency stop, overload protection

- Rotating table or tumblast conveyor (depending on model)

- Cartridge Type Pulse-Jet Dust Collector integrated

- 6-8 bar (87-116 psi), dry and oil free

- Manganese Steel lined for extra durability

- 2 - 4 pneumatically operated nozzles

- PLC Controlled with touch screen HMI interface

- Electronic, programmable shot flow control system

- <80 dB(A) under operation

Automatic Air type Shot Peening Machine Product Specifications

- Fully Enclosed Automatic Air type with Pneumatic Shot Delivery

- Approx. 3800 kg

- Surface finishing, stress relieving, deburring, shot peening for aerospace, automotive, and metal fabrication industries

- Three Phase Electric Motor

- Variable, typically 50-300 kg/hr depending on part size and shot material

- 380V / 415V, 50Hz (Customizable as per requirement)

- 3200 mm x 2200 mm x 3500 mm

- 7.5 kW to 22 kW (based on model)

- Automatic air-wash and vibratory screening

- Interlocking doors, emergency stop, overload protection

- Rotating table or tumblast conveyor (depending on model)

- Cartridge Type Pulse-Jet Dust Collector integrated

- 6-8 bar (87-116 psi), dry and oil free

- Manganese Steel lined for extra durability

- 2 - 4 pneumatically operated nozzles

- PLC Controlled with touch screen HMI interface

- Electronic, programmable shot flow control system

- <80 dB(A) under operation

Automatic Air type Shot Peening Machine Trade Information

- 10-15 Piece Per Month

- 1 Months

- Standard Packaging

- South America, Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, Asia, Africa

- All India

Product Description

Being a famous organization, we have involved as the famous manufacturer of an advance Automatic Air Type Shot Peening Machine. Offered machine is a cold working technique used to meet metal parts and to change different mechanical features of materials. Our provided machine is made by the use of stainless steel & rust free in nature. Our offered Automatic Air Type Shot Peening Machine is used to increase in fatigue strength under torsion and bending, which prolongs product life. The workpieces finished are mainly metal parts. The metal part cracks and corrosion resistance increases as this shot peening process creates small dimples in the surface that cause compression stresses. This machine also features flexible mechanism for loading and unloading. The operator can adjust the air pressure and media feed. Our customers can get this machine from us at market leading rates.

Automatic Air Type Shot Peening Machine Features:

- System that is extremely dependable

- Durable construction

- Assurance of performance

- Each coil spring is treated separately.

- The parameters for shot peening can be set using the operator's panel.

- Very economical to use

Advanced Pneumatic Shot Peening Technology

Utilizing 2 to 4 pneumatically operated nozzles and programmable electronic shot flow control, this machine delivers precise and reproducible peening results. Suitable for demanding environments, it supports complex surface finishing, stress relieving and deburring tasks for various industries, including aerospace and automotive.

Durability & Integrated Safety

With its blast cabinet lined in manganese steel, the equipment guarantees longevity, even in heavy-duty operations. Safety is ensured by interlocking doors, emergency stop functionality, and overload protection. These integrated features help sustain safe and uninterrupted processes.

Seamless Operation & Versatile Handling

The shot peening machine offers advanced work handling via rotating table or tumblast conveyor, enhancing versatility for parts of different sizes. Its compact, fully enclosed design, coupled with effective air-wash and vibratory screening, ensures a dust-free, efficient, and user-friendly workflow.

FAQs of Automatic Air type Shot Peening Machine:

Q: How does the programmable shot flow control benefit the peening process?

A: The electronic, PLC-based programmable shot flow control system ensures consistent and precise shot delivery, enabling accurate reproducibility across parts and reducing the risk of over- or under-peening, thereby optimizing surface finish quality.Q: What types of parts and industries can use this automatic air type shot peening machine?

A: This machine is ideal for components in aerospace, automotive, and metal fabrication sectors, handling tasks such as surface finishing, stress relieving, and deburring for parts suited to the variable 50300 kg/hr capacity.Q: When should the dust collector cartridges be changed or maintained?

A: Routine maintenance depends on usage frequency and material processed. However, as a general guideline, cartridges in the pulse-jet dust collector should be inspected monthly and replaced or cleaned when performance drops or filter clogging is observed.Q: Where can this machine be installed, considering operational and safety requirements?

A: It should be installed in industrial environments with adequate space (dimensions: 3200 mm x 2200 mm x 3500 mm), access to a suitable power supply (7.522 kW, three-phase, voltage as required), and available dry, oil-free compressed air at 68 bar.Q: What safety features are incorporated in this shot peening machine?

A: The machine is equipped with interlocking doors to prevent access during operation, an emergency stop button for immediate shutdown, and overload protection to guard both operators and equipment.Q: How is media automatically recovered and filtered in this equipment?

A: An integrated air-wash and vibratory screening system automatically separates usable shot from debris and dust, ensuring only clean media is circulated back into the peening process, thus maintaining operational efficiency.Q: What are the core benefits of using a manganese steel-lined blast cabinet?

A: Manganese steel lining significantly enhances cabinet durability and resistance to abrasion, minimizing downtime and maintenance coststhus extending the machines operational life in high-throughput environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese